Dump Silo

Tipper Silo Technical Specifications:

Silo Capacity (Volumetric): Volumetric production is made between 28-50m³ according to customer order.

Body Quality: High-strength ST52 or Strenx brand Swedish steel is used as body material quality.

Payload With the light weight of the body, the payload reaches maximum values.

Body Type: The body is cylindrical and manufactured by certified and specialized welders.

Working Pressure: The working pressure of the silobas is 2 bar and the test pressure is 3 bar.

Axle Arrangement: 3 axle chassis layout is available.

Materials: High-strength frame steel and sleepers are used in accordance with EEC directives.

Manufacturing: During chassis assembly, the optical laser measuring device is used to ensure smooth and flawless chassis manufacturing.

Assembly Method: Trailer ears are assembled and welded to the chassis lam by sword manufacturing method.

Suspension Bellows, (single/double) folded Z truss suspension system is used.

Front Axle: The front axle is lifting controlled from the towing cab.

Number of Axles: 3 x 9 tons carrying capacity drum or disc axle system is used.

Axle Brands: Sertel, Pırlanta etc. (Domestic) / BPW, SAF (Ital) (Preferences are optional.)

Brake System: WABCO 2S-2M EBS + RSS is assembled in accordance with ECE R13 BM / AEK Regulation.

Dumper movement: It is realized by HIDROMAS brand 5-stage heavy type telescopic cylinder providing 45º tilting angle.

pneumatically controlled: Damper is pneumatically controlled, with double speed lowering valve and limit control safety.

Intermediate Connection: The connection between the tow truck and the trailer is provided with 2 jacks. It is mounted to the customer vehicle with the appropriate PTO.

Electrical System: SA-BA (Varroc) brand 2×7 & 1×15 pol connections in accordance with UN/ECE regulation ECE R48 and socket in accordance with ISO 12098.

King-Pin 2″ bolted King-Pin with DIN 74080 quality and in accordance with ECE R55 is used.

Mechanical Foot: OMS/GOS brand OMS/GOS foot with gear transmission with 24 tons dynamic and 50 tons static load capacity is used.

Tire and Rim: R22.5 x 385/65 PIRELLI R179 tires and 11.75 x 22.5 steel wheels are preferred and assembled in accordance with EU/458/2011 regulation.

Paint All metal surfaces are primed with 2 coats of epoxy paint after sandblasting and then painted with 2 coats of acrylic paint in the desired RAL code.

MARKING and LABELS:

– Mandatory labels, rear reflectors, reflective strips, speed signs and warning labels in accordance with EU/19/2011 regulation.

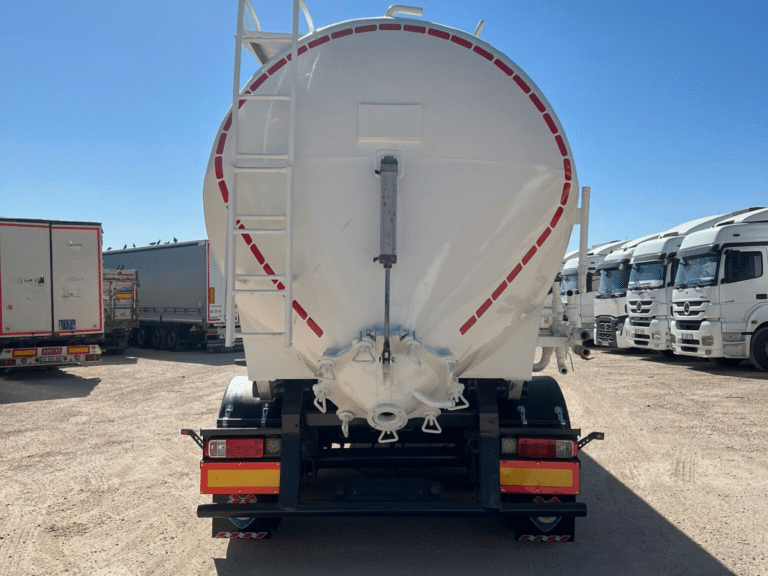

Pressure Vessels: DN 400 – DN 500 diameter manhole cover designed and manufactured in accordance with 97/23/EC Pressure Vessels regulation.

Upper Filling Covers: There are 3 butterfly bolted tightening on the upper filling caps.

Pressure Vessels: After the damper is lifted at an angle of 45°, air is supplied into the boiler with the help of a compressor.

Discharge When the manometer shows 2 bar air pressure, the 4″ ball valve on the back cover of the dump silo is opened and the product inside the boiler is transferred to the outside.

– Thus, the discharge of the product inside the dump silo starts.

STANDARD ACCESSORIES

– Folding Rear Bumper according to ECE R58 BM/AEK

– Bicycle Guardrails in accordance with ECE R73 UN/ECE

– 4″ Flanged SEL brand Discharge Hose

– Mudguards

– Lockable Material Cabinet (80 Lt.)

– Wheel Chock

– Rear Bumper Mat

– Water Tank

– Fire Extinguisher Cylinder cabinet

– SA-BA (varroc) Electric Set

– Spare Wheel Carrier

– Lug Wrench & Lever

– Rear Exit Staircase

– 2″ Relief Valve with 4 Bar Pressure resistance

– Glycerin Manometer

OPTIONAL FEATURES

– JOST Lift Leg

– JOST King-Pin

– ALCOA Aluminum Wheel

– ASPÖCK Electrical Set

– WABCO SMARTBOARD / e TASC

– Middle Axle Lift System

– Pneum. Foldable Top Walking Sightseeing Platform (h:1100 mm)

– PVC Tubular Enclosure for 4″ Discharge Hose

– Special Advertising with Glue on Silobas Body

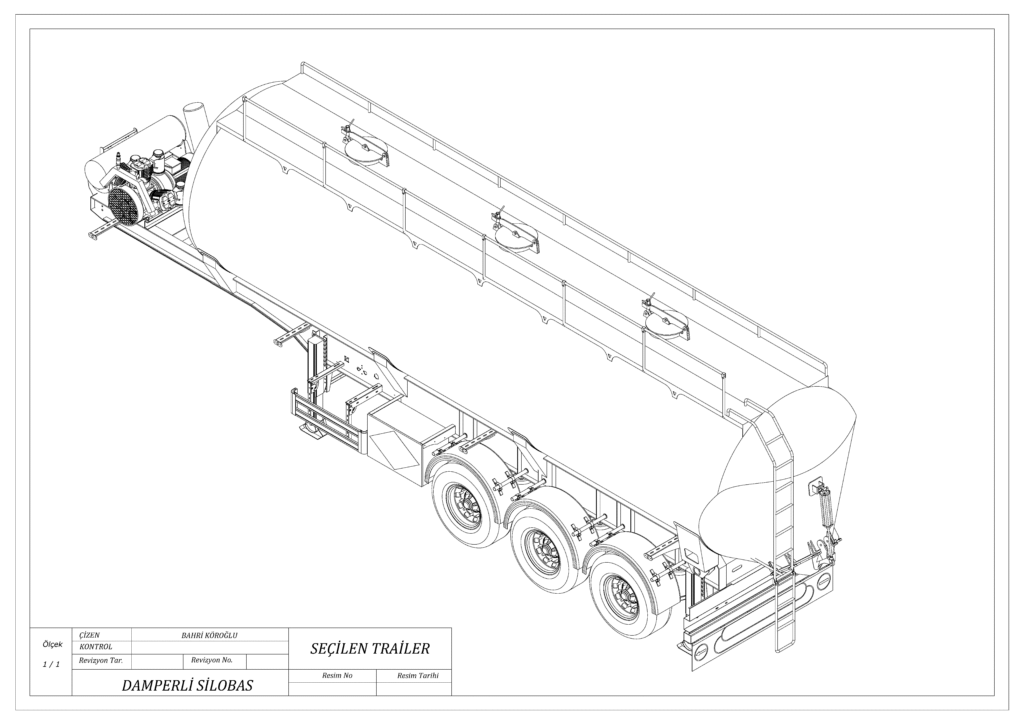

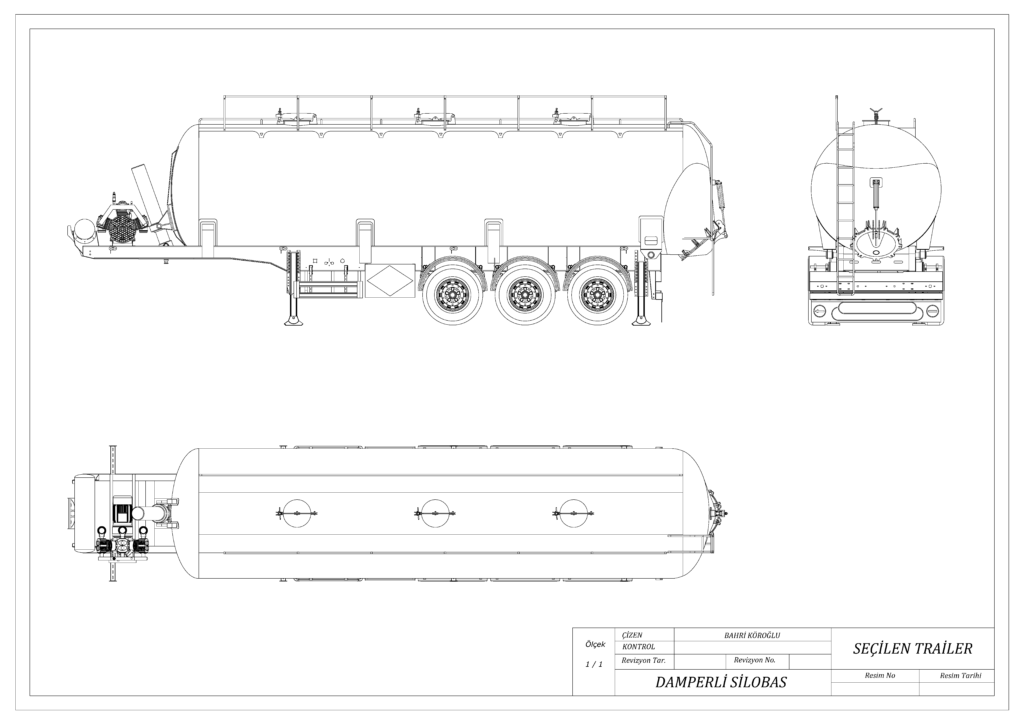

Dump Silo Technical Drawing: